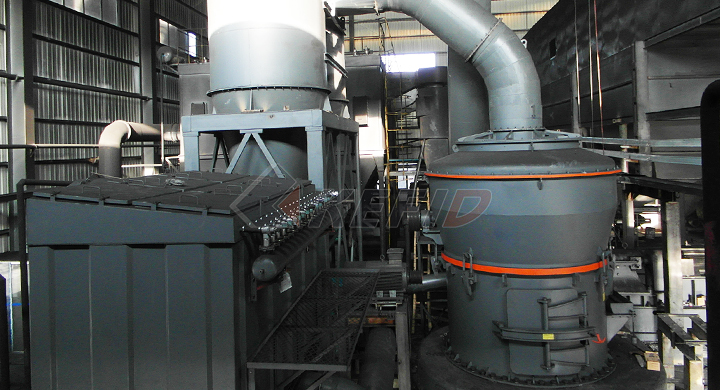

Vertical grinding mill

VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry mills. With a decade of research of mills, vertical grinding mill is designed and manufactured based on our advanced design idea, in combination with the european technology and the market demand. VM Vertical Roller Mill adopts reliable structure and reasonable process flow, integrated with drying, milling, classifier, elevator. Especially, it can fully meet the requirement of clients of the high production of powder, and its main technical and economic indicator reaches the international level.

Output size : 80-325 mesh

Production capacity : Up to 128TPH(ore mill), up to 50TPH (coal mill)

PROCESSED MATERIALS

Pyrophillite, coal, calcite, barite, limestone, lime powder, marble, silica, talc, kaoline, gold ore, ferrite, clay, slag, marble,and so on.

APPLICATIONS

Glass fiber industry, coal industry, chemical industry, and for large scale powder making and non mental mine industry.

PERFORMANCE

1. Low operating costs

Combine the crushing, grinding,dring, classifier and elevator , the system of vertical mill is simple and occupation area is about 50% of ball mill system. It can be installed outside, so it will reduce a large number of investment cost;

2. High efficiency

Compared with ball mill, vertical mill can save energy consumption 30%-40%;

3. Less wear and tear

The optimized roller and the high quality raw material make the machine’s life more longer;

4. High dring ability

As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with diffirent humidity;

5. Simple and reliable operation

Automatic control system is equiped, so the remote control makes it easy to operate. It is equipmented with one device,which prevents the roller from contacting with the liner directly, and avoids the destructive impact and severe vibration;

6. Convenient maintenance

By reparinging fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime loss;

7. Environmental protection

It is with small vibration, low noise, and the overall sealing. The system works under negative pressure, so there is no dust going out. It meets the requirements of the state Environmental Protection.